2016-04-20

Precision clamping technology as a standard solution

RINGSPANN offers complete clamping fixtures for machining

There are only a few manufacturers in this country who offer such a versatile precision clamping fixture system for the machining of workpieces with cylindrical internal and external surfaces as RINGSPANN does. Only recently, the company extended its current overall range to include a new standard series of ready-to-use flange chucks and flange mandrels for clamping diameters from 7 mm to 560 mm. With a true running accuracy of ≤ 10 µm, these complete systems are an ideal solution for many metal-cutting processes in production engineering. Renowned machine tool manufacturers also recommend them for the machining of thin-walled components.

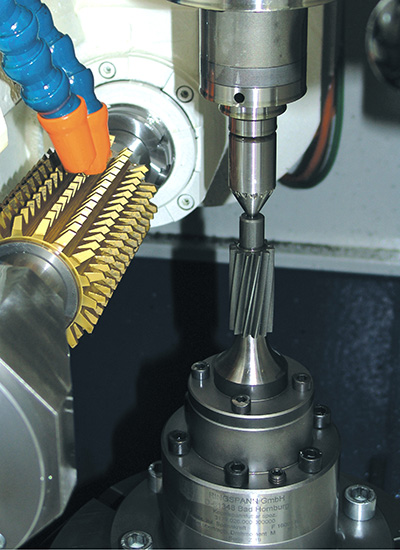

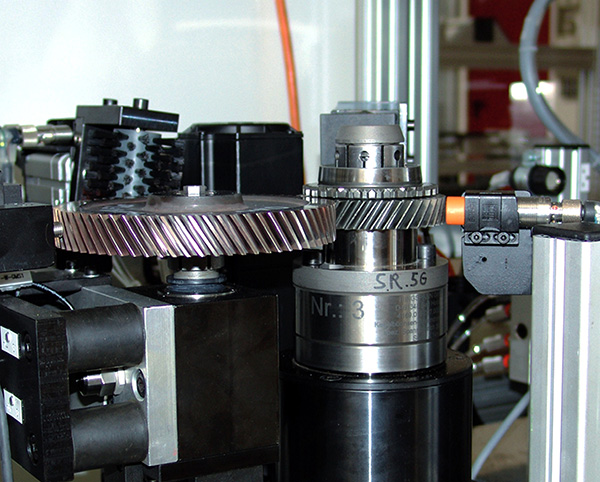

Bad Homburg, April 2016. – Drawing on its 70 years of experience in the development and production of efficient precision clamping fixtures for all relevant metal-cutting processes, RINGSPANN has brought out a new series with a total of nine chucks and mandrels, which can be used for a great number of lathing, milling and grinding processes with increased accuracy requirements. Wherever metallic components with cylindrical internal or external surfaces need to be machined in the automotive and gear manufacturing or aerospace industry, these standard clamping fixtures from the Bad Homburg company are an ideal "interface" between the machine tool and workpiece. They are a particularly ideal solution for the production of gear wheels and for balancing technology. Renowned machine tool manufacturers also recommend the new RINGSPANN clamping fixtures to their customers for the internal or external clamping of thin-walled workpieces, which, owing to their propensity for deformation, require a particularly careful clamping technology with even force transmission.

The standard redefined

When designing and putting together the new standard series, the development engineers at RINGSPANN had one main aim in mind: To provide an extensive selection of quick-to-use and versatile complete clamping fixtures to users in many industries, enabling them to effectively meet the increasing requirements regarding precision and the reduction of set-up and cycle times. And the RINGSPANN experts ended up achieving much more! They have realised, based on the functional principle of the RINGSPANN clamping disc, four new chucks and five new mandrels, allowing large machining moments to be transferred in the case of clamping diameters of 7 mm to 560 mm and true running accuracies of ≤ 10 µm, both in external and internal clamping. And also in the case of short clamping lengths, high workpiece tolerances and long insertion depths! The new standard series by RINGSPANN is therefore suitable for a very wide range of applications.

Even all-around gripping

The practical application of the new precision clamping fixtures by RINGSPANN is quite simple, irrespectively of the construction type: when clamping, the workpieces are centered, pulled against the true backstop surface and aligned thereby. The clamping fixture evenly grasps the entire circumference of the workpiece. This rules out any eccentric deformation and permits an accurate, firmly-enclosing all-round clamping – which explains the special suitability for workpieces where deformation is a critical factor! The actuating force applied to the clamping fixture is translated without friction into a five to ten times greater radial force for clamping the workpiece. In practice, this ultimately makes the transmission of high torques possible as well as a higher metal-cutting performance.

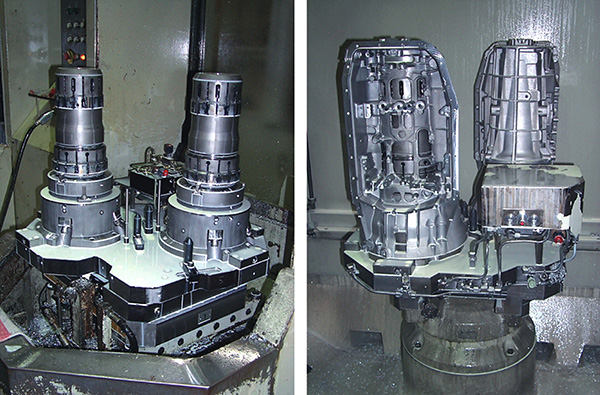

The new standard clamping fixtures by RINGSPANN have already been able to demonstrate their efficiency in numerous areas of application. For example: in the milling of truck crown wheels, in the lapping of motorcar crown wheels, in the grinding of helical gearings of spur wheels, in the milling of gear components for wind energy plants, in the machining of turbine stages, in the clamping of gear wheels for noise tests and in many other cases as well. To optimise their manufacturing processes, several famous machine tool manufacturers now recommend their customers the new standard clamping fixtures by RINGSPANN as a clamping technology solution which is economical and versatile in equal measure.

Standard in nine basic executions

RINGSPANN supplies its new standard clamping fixtures in nine different executions. Depending on the case of application, the user has the choice between four flange chucks or flange mandrels in bonded disc, taper collet, taper sleeve or flat element designs. As a ninth variant, there is a taper collet centre mandrel. What all clamping fixtures have in common are their high service life with minimum maintenance and an insensitivity to dirt. With the new standard series from RINGSPANN, the user therefore gets a highly efficient and future-proof clamping solution.

Not to mention: the development and realisation of individual and customised special productions in the area of clamping technology has great tradition at RINGSPANN. If required by the case of application, the company can also provide extraordinary clamping systems – such as highly complex segmented diaphragm clamping chucks and mandrels for clamping diameters of up to 1600 mm!