2017-10-18

”In terms of energy efficiency already unbeatable”

Push-pull cables by RINGSPANN RCS offer unique dynamic and cost benefits

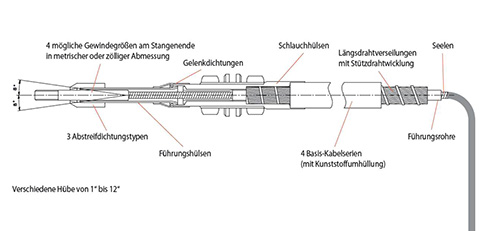

The engineers of safety and rescue systems often don’t have a choice. When emergency trigger, unlocking or release functions cannot fail under any circumstances, electrical, pneumatic or hydraulic devices are normally ruled out. Purely mechanical control, actuation and operation elements such as long-term tested push-pull cable systems by RINGSPANN RCS are the better choice in such cases. Product developers in other fields of application are also increasingly discovering the ready-to-install “remote control systems” as both a cost and energy-saving solution for bi-directional power transmission.

Oberursel, October 2017. – When it comes to designing trigger, unlocking or release functions of safety and life-saving systems for engineers in marine engineering and in aircraft construction, purely mechanical solutions are usually preferred for power transmission. Sometimes it is because of the susceptibility against electromagnetic interference fields, sometimes it is leakage issues or too high maintenance costs that make the installation of electronic, hydraulic or pneumatic systems seem too risky or too expensive. Even mechanical linkage and swivel joint devices are avoided where possible, as they are normally too vulnerable and maintenance-intensive. Their ideal solution in many cases consists in using flexible RINGSPANN RCS push-pull cables. Push-pull cables are high-quality and extremely reliable remote control systems for mechanical power transmission in two directions. Current market observations of the manufacturer confirm that increasingly, more and more product developers in other fields and industries are employing the easily integrated control, actuation and operation elements. And even in robotics, machine tool engineering and fluid technology, more and more engineers (and purchasers) are reaping the rewards of the practical benefits these remote control solutions offer.

Push-pull cables in system comparison

A direct system comparison immediately makes clear what makes these push-pull cables from the Oberursel manufacturer’s portfolio so special. Technically related to the Bowden cable – which albeit only transfer pulling forces – what sets them apart from rigid mechanical constructions is their flexible laying compatibility, their low space requirement and their service-friendliness. Lever linkage solutions not only require regular lubrication, they often need to be protected by channels, bellows or housings against splash water, dirt and foreign bodies. This leads to additional costs in construction and subsequent time-consuming installation and disassembly works. “Our cable systems, on the other hand, are already protected ex works against splash water and lubricated for the intended life cycle as standard – meaning they are maintenance-free for the calculated duration of operation”, says Christian Kny, managing director of RINGSPANN RCS.

Mechanically flexible instead of complex

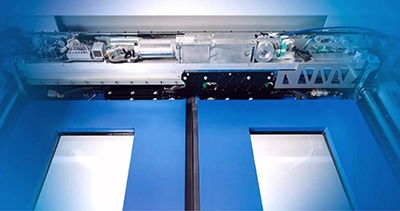

Compared with electrically driven actuation and operation systems, the purely mechanical power transmission with RCS cables has the benefit of not per se requiring either a power supply or an electrical consumer. This means there are no electrical installation costs, which plays a key role particularly during the development of safety-relevant devices and systems! An invaluable advantage – particularly when being deployed in electromagnetically sensitive environments – is additionally that their purely mechanical operating principle rules them out as a source of electromagnetic interference fields. The same feature also makes them immune to electromagnetic interference, which is why they cannot be maliciously manipulated in this regard. “And in terms of energy efficiency, our push-pull cables are already unbeatable”, adds Christian Kny.

The energy efficiency argument is also significant when carrying out the direct system comparison of the push-pull cables with hydraulic and pneumatic solutions. Many engineers – and technical purchasers – meanwhile see another factor as being much more important: While initially, the construction, and later, the subsequent operation of maintenance-intensive hydraulic and compressed air systems always mean significant time and cost expenditure, using RINGSPANN RCS remote control systems means such costs can in some cases be eliminated completely. And yet managing director Christian Kny is keen to emphasise the useful combination of these different system worlds: “In many cases, it is our push-pull cables that transfer hydraulically or pneumatically generated forces – for example to difficult-to-access areas or in zero-leakage applications. On the other hand, force transmission can also be carried out with their assistance, for example if the control of a pressure accumulator or hydraulic unit is to be solved mechanically.”

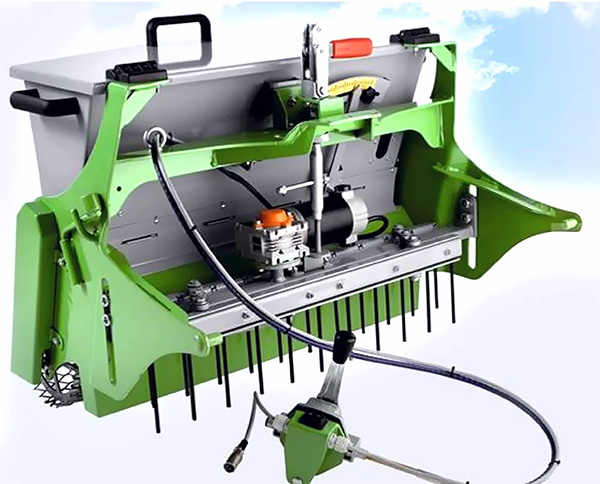

Accelerating and delaying forces

Moreover, the cable specialists of RINGSPANN RCS know of application cases in which accordingly designed push-pull cables can even be employed for the acceleration and delay of moving masses. The advantages of the light and flexible cables are hereby particularly founded in their low own mass and in the fact that they largely prevent the transmission of vibrations. This, for example, benefits the realisation of mass-optimised lightweight constructions – for instance in sophisticated positioning and feeding systems. The drives can hereby be positioned in an uncritical location and the push-pull cables transfer the generated force to the distant-lying – and possibly difficult-to-access – actuator. “Our push-pull cables have proven themselves to be cost-effective solutions for a mass-reduced power transmission especially for applications that do not require extremely short response times. However, such demanding tasks require great care in the technical design of the cables and lots of experience”, underscores managing director Christian Kny.

In principal, RINGSPANN RCS push-pull cables offer a solution for all structures in which forces need to be transferred maintenance-free between spatially separated modules and where it should be possible to separate the direct connection of input and output force with a flexible system. Engineers who are faced with such a task and are unable to use electrical or fluid-technical units for financial reasons should take a closer look at the premium-processed push-pull cables from Oberursel. Especially when it comes to power transmission in critical environments – for example in potentially explosive, environmentally sensitive applications or applications sensitive to magnetic fields.