2023-11-20

In case of direct contact in stainless steel

Shaft-hub connections from RINGSPANN prove themselves in the food industry

RINGSPANN is currently equipping plant manufacturers in the Food & Packaging market segment with high-quality shaft-hub-connections on an increasing scale. Designers in the industry can choose between the standard series of the RLK family or stainless steel shrink discs and nickel-plated clamping sets or even OEM-specific special solutions. Typical applications for these machine elements include the drive trains of agitators, conveying and mixing systems as well as filling and packaging systems.

Bad Homburg, November 2023. – „RINGSPANN’s frictional shrink discs and shaft-hub connections are currently attracting increasing interest from designers of food packaging and processing systems. “This may be primarily due to the fact that we have gradually expanded the range in this part of our one-stop shop for industrial drive technology and already optimized numerous series some time ago using an improved frictional connection calculation method,” explains Marvin Raquet, Product Manager for RINGSPANN's shaft-hub connections. Another reason for this development is likely to be that, in addition to the catalogue series of its RLK line, the company is increasingly also producing stainless steel shrink discs, nickel-plated clamping sets and custom-made products. With this wide range of products, it can supply designers in the Food & Packaging sector with shaft-hub connections for drive systems that do not come into direct contact with food, as well as shrink discs and cone clamping elements for drive units that come into direct contact with food. “With the ability to meet specific OEM requirements, we are also an attractive innovation partner for plant manufacturers in the food industry,” says Marvin Raquet.

Solutions for internal and external tension

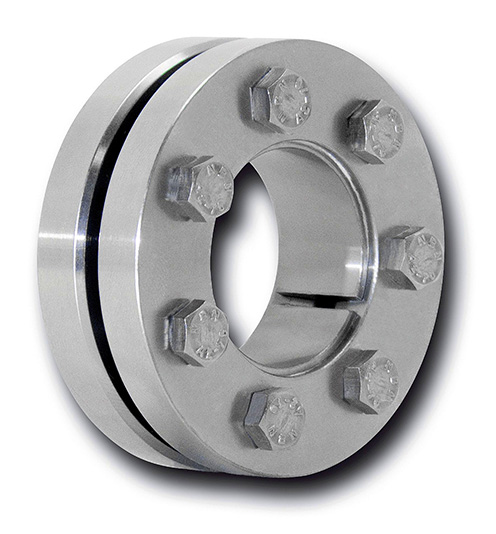

Currently, it is primarily the drive systems of belt conveyors, agitators and mixers, as well as beverage filling and food packaging systems, in which the shaft-hub connections from RINGSPANN are installed. The shrink discs of the RLK family are used for the realization of backlash-free external clamping connections of hollow shafts (or hubs) on shafts, while the RLK cone clamping elements serve as backlash-free internal clamping connections of hubs on shafts. Depending on the version, the shrink discs transmit torques of up to 4,025,000 Nm, while the torque capacities of the cone clamping sets range up to 1,701,000 Nm. These two parameters alone give an idea that RINGSPANN currently covers all conceivable applications in the food & packaging sector with the technical range of its shaft-hub connections. The diameters of the shafts may be between 6 and 620 mm in the standard segment. With the exception of the RLK 300 type, all shrink discs and clamping sets are actuated with integrated screws. With a few exceptions, they centre the hub to the shaft and do not cause any axial misalignment of the hub during the clamping process. “These are factors that make our shaft-hub connections practical plug-and-play solutions that can be installed quickly without additional design effort,” explains Marvin Raquet.

In stainless steel or with nickel-plated surfaces

While the steel shaft-hub connections of the RLK line from RINGSPANN are an economical solution for drive systems in the non-food-carrying sector, the corrosion-resistant stainless steel shrink discs of the RLK 603 K series and the nickel-coated cone clamping sets of the RLK 110 K series prove to be the first choice for drive trains that come into contact with food.

The stainless steel RLK 603 K is designed as a three-part assembly with which hollow shafts or hubs with outer diameters from 24 mm to 175 mm can be clamped on rotating shafts. It transmits torques from 170 Nm to 23,000 Nm. Such a premium shrink disc is, for example, part of a rotationally adjustable attachment of a beater to the gearbox of a hygiene-sensitive screening plant for baking agent conditioning. “The design of the shrink disc and all screws in stainless steel allows the realization of a drive solution that is easy to maintain and clean,” explains Marvin Raquet.

The cone clamping elements of the RLK 110 K series, which are suitable as internal clamping connections for shafts with diameters from 19 mm to 60 mm, already have nickel-plated surfaces as standard. This allows torques between 190 Nm and 2,800 Nm to be transmitted, whereby these clamping elements from RINGSPANN are particularly well suited for hubs with smaller outer diameters thanks to their radially flat height. The nickel coating with a standard thickness of 35 μm gives them high corrosion resistance in accordance with DIN 50021. If only less corrosion protection is required and the budget is tight, thinner layer thicknesses can also be achieved,” says Marvin Raquet.

By the way: The RINGSPANN manager and his team are currently experiencing a growing demand for corrosion-resistant shaft-hub connections. The triggering factor for this is likely to be, among other things, the steadily increasing hygiene requirements that characterize the work of designers in food technology. ms

Transmission of torques without loss

In order for a drive shaft to be able to transmit its rotating force without loss, it needs a secure and firm connection to the hub or shaft of the machine element to be moved. For this purpose, RINGSPANN offers an extensive portfolio of frictional shaft-hub connections, which – depending on the design – can transmit both torques and axial forces. The current product catalogue provides a complete overview of the current portfolio of two- and three-piece shrink discs, cone clamping elements as well as star discs, star springs and torque motor clamping systems.